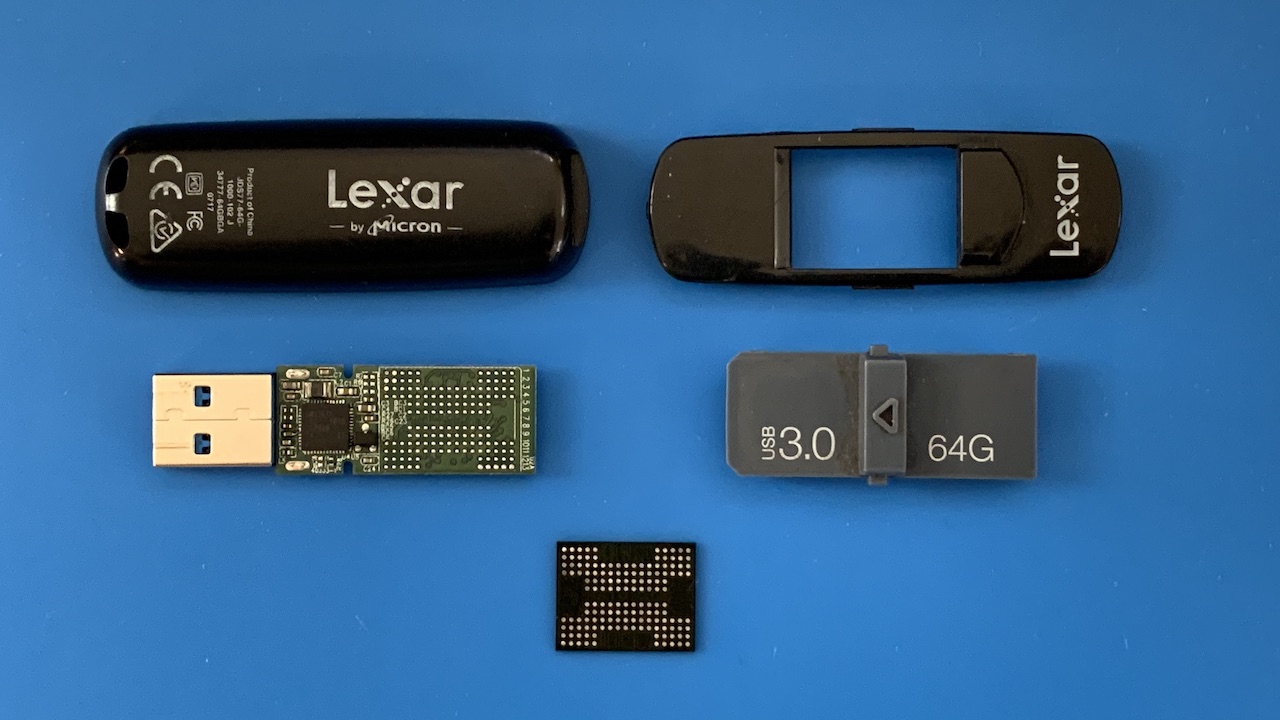

Preparing BGA (ball grid array) Flash memory microchips for data recoveries vary based on the form factor and type of device used. However, regardless of device type, the first step is always to extricate the circuit board holding the BGA chips from their protective housing. Some devices such as solid state drives (SSDs) require only a screwdriver for disassembly.

Other devices, like USB Flash Drives, typically require mild prying force to disassemble their cases. Oftentimes, isopropyl alcohol (IPA) and low heat from a hot air re-flow station or heat gun facilitate the disassembly process.

Preparing BGA Flash Chips for Removal

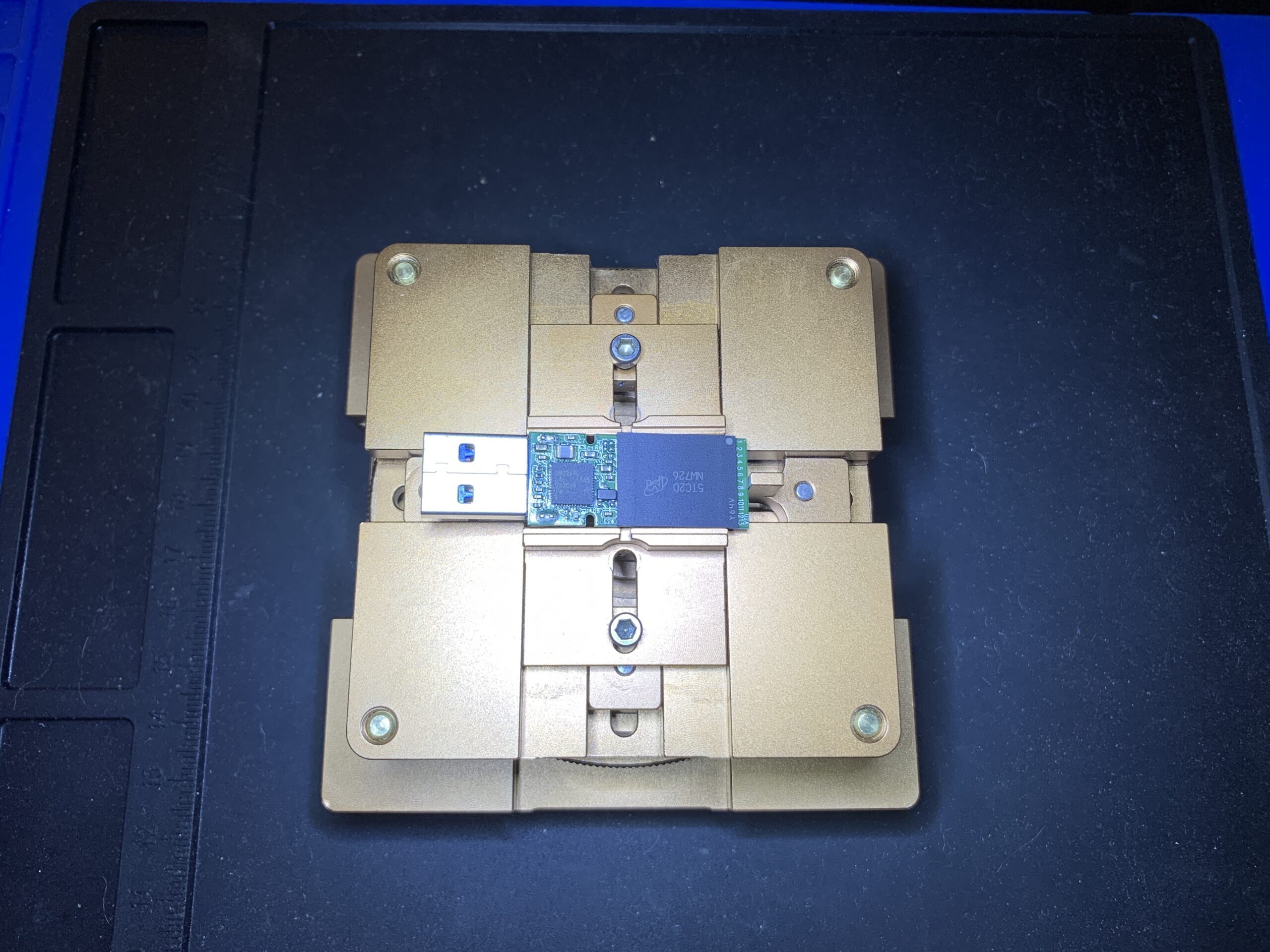

Firstly, prepare the work area by protecting it with one or multiple silicone mats. These mats are inexpensive, easy to clean, and can sustain temperatures of up to 932ºF (500ºC). Next, mount the circuit board containing the BGA chips in an appropriate sized vice. Lastly, position the fume extractor hose nozzle near the vice so it can trap and filter the residual, toxic fumes.

Desoldering a BGA Chip Using a Hot Air Station

Firstly, apply flux to the sides of the BGA chip where heat. Add enough flux so it flows underneath the entire chip when heated.

Next, set the heat and airflow settings of the hot air station. I recommend somewhere between 450ºC to 500ºC.

Thirdly, turn on the fume extractor. Flux fumes are extremely hazardous and contain known carcinogenic compounds. As much as possible, avoid exposing yourself, your tools, and your work area.

I use a Hakko FA-430 fume extractor. The regular, white pre-filter and main filter set removes up to 98% of material down to 0.3 microns. The orange, HEPA pre-filter and main filter set reduces 99.8% of material down to 0.3 microns.

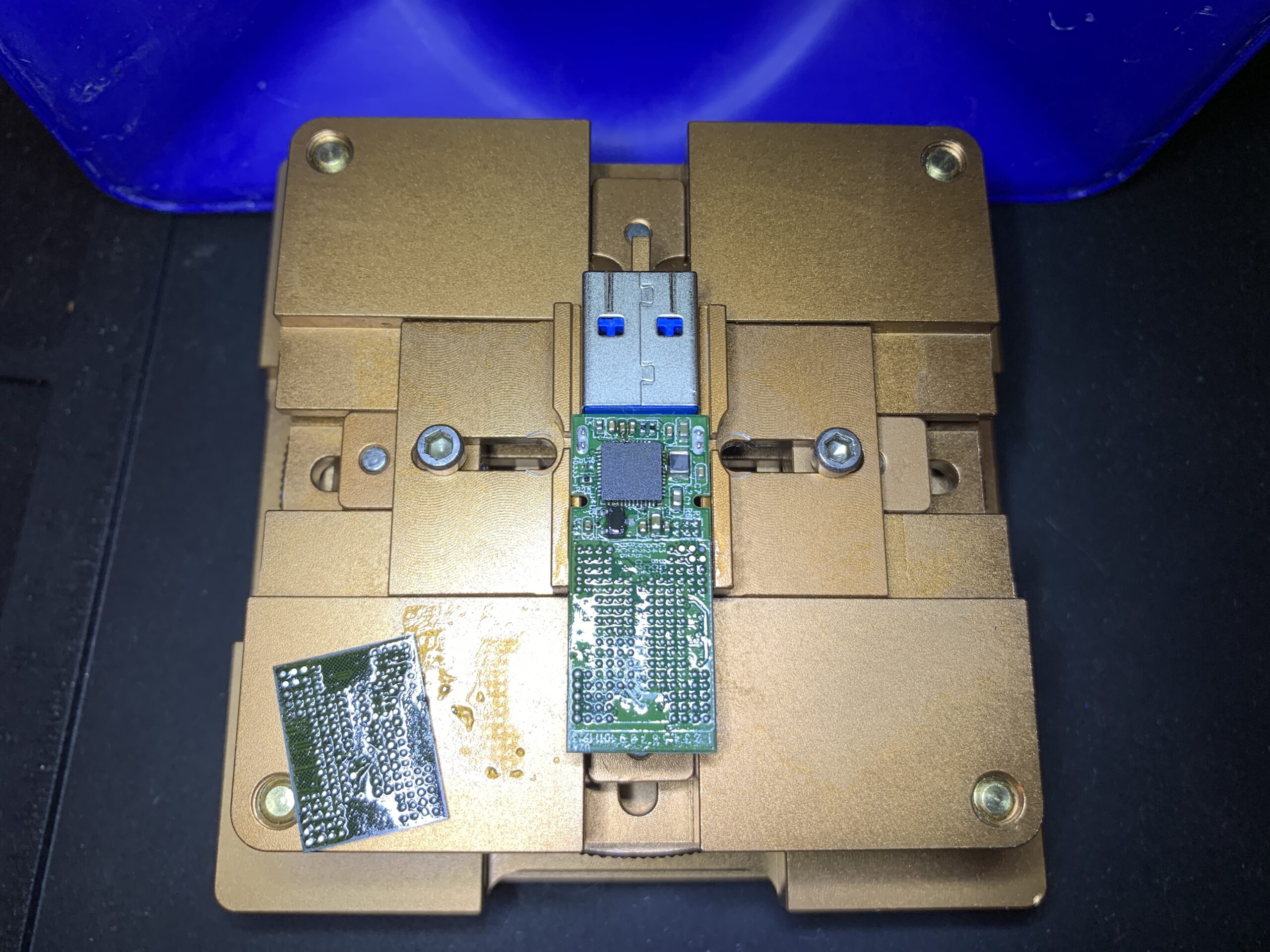

Lastly, apply heat to the BGA chip. Confirm the flux and hot air melted all of the solder balls holding the BGA chip in place by slightly tapping the chip from the side. If the chip moves slightly then snaps back into location, remove it carefully with a suction tool, tweezers, or slide it off of the circuit board with a heat resistant tool.

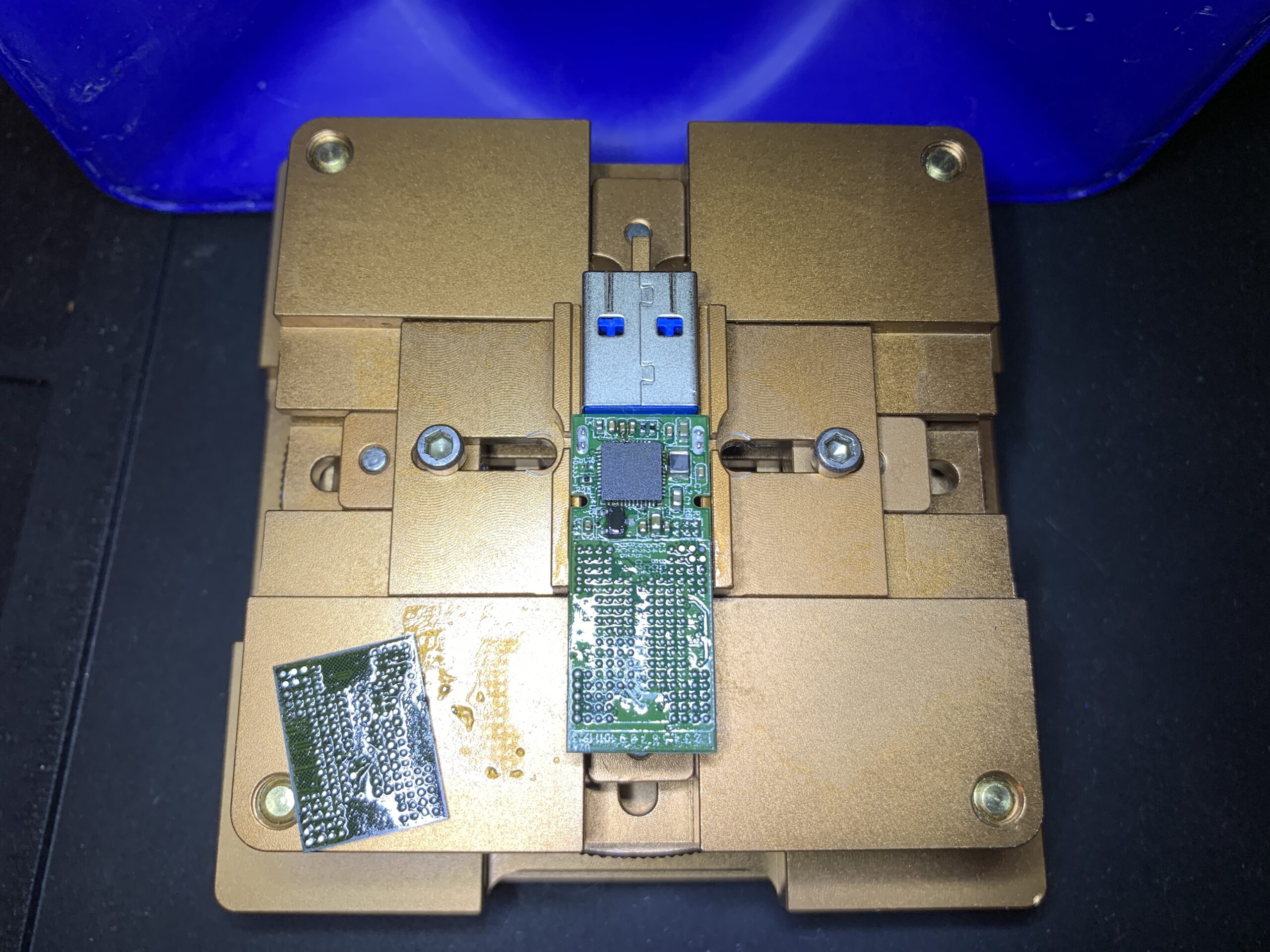

Preparing BGA Flash Chip Pads

Before a BGA Flash Memory Chip is placed in a pogo pin, or spring-loaded pin, adapter, the pads of the chip must be cleaned of solder. Firstly, I apply flux and leaded solder to the pads using a soldering iron.

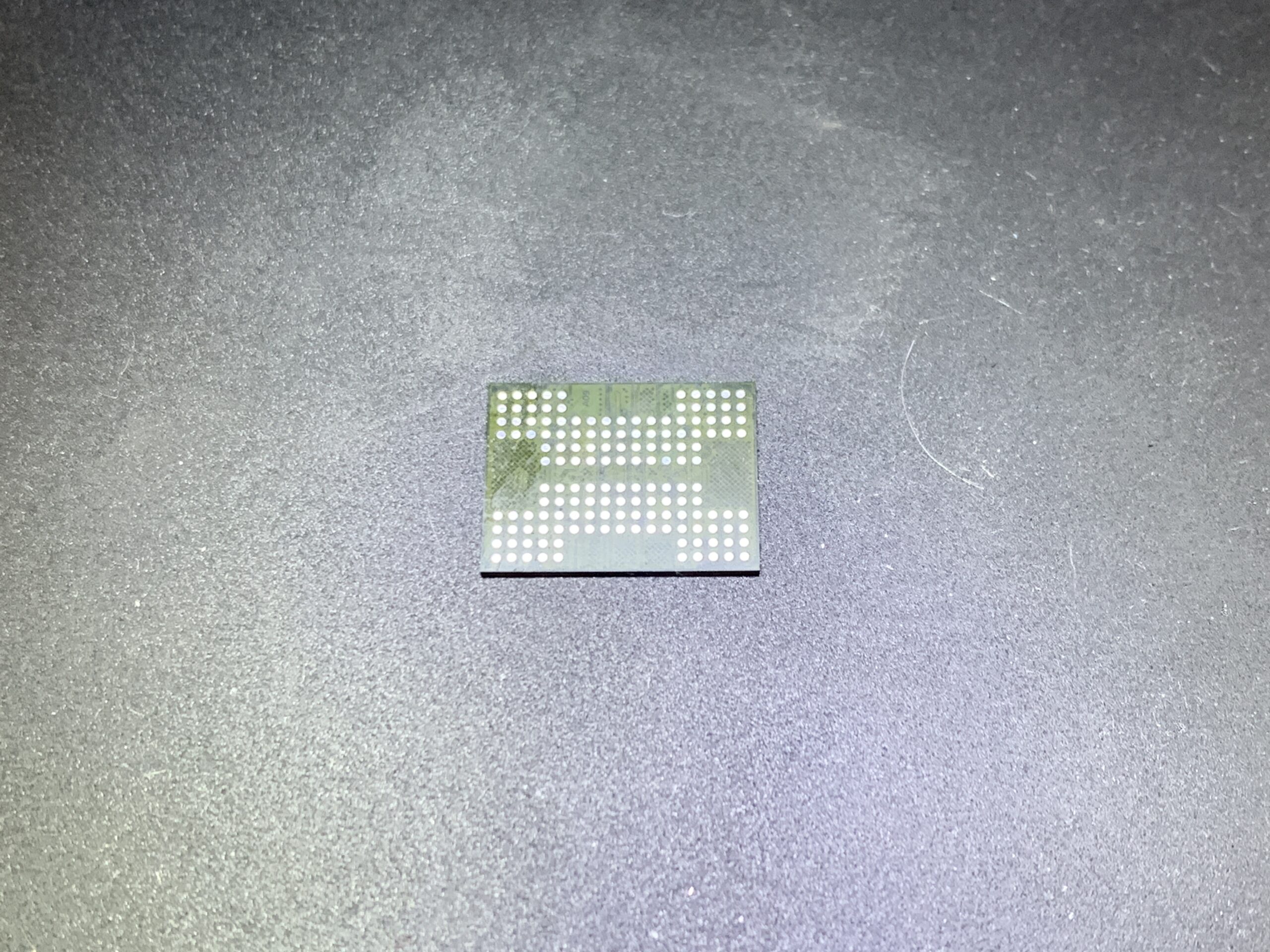

Next, I use solder wick to remove all of the solder from all of the pads. I use two different techniques to wick pads clean of solder. The first technique uses a hot air station to melt the solder on the pads. Then, the pads are cleaned by brushing the solder wick gently over the pads. The second technique uses a soldering iron in direct contact with the solder wick to melt the solder on the chip pads.

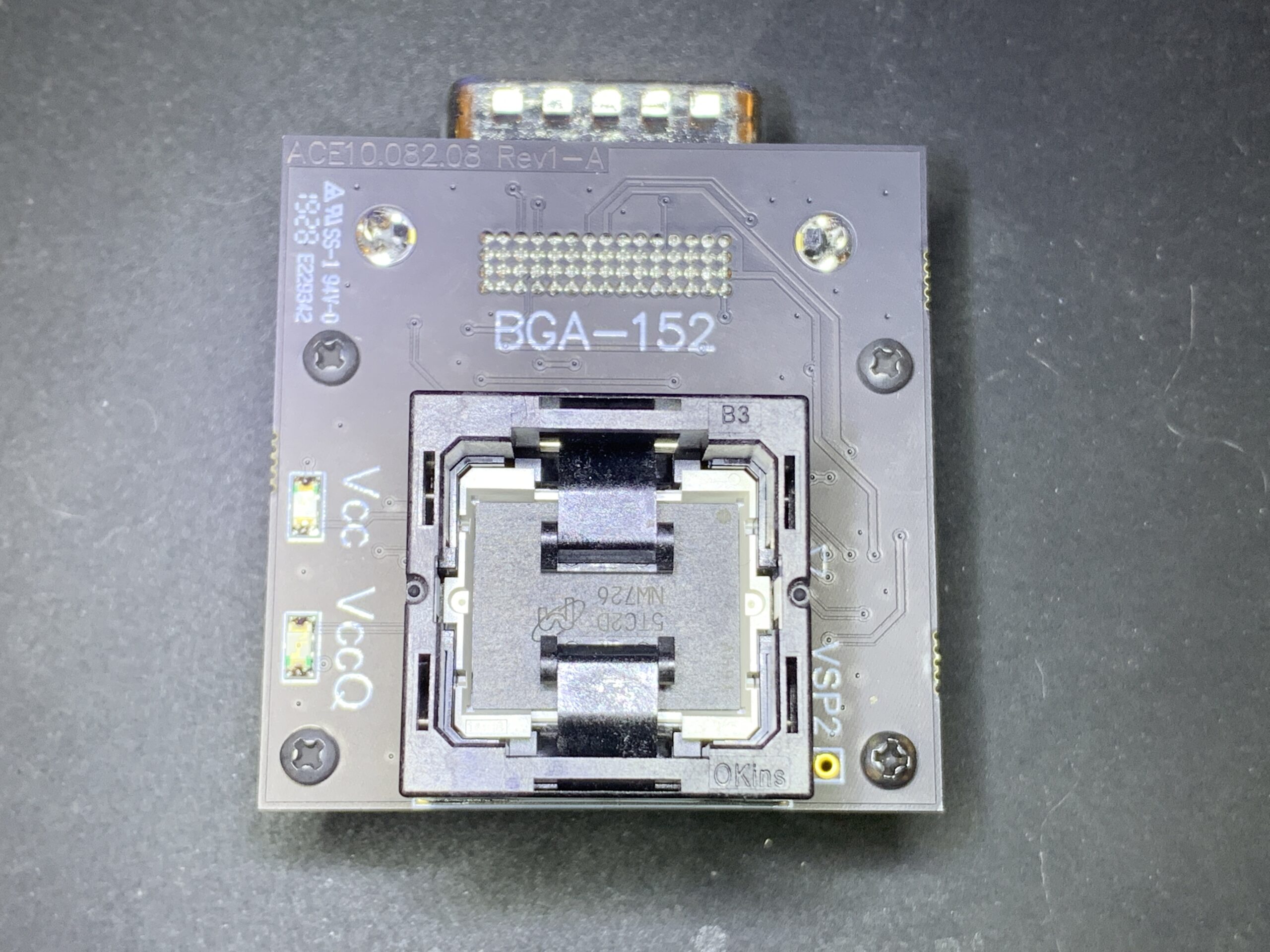

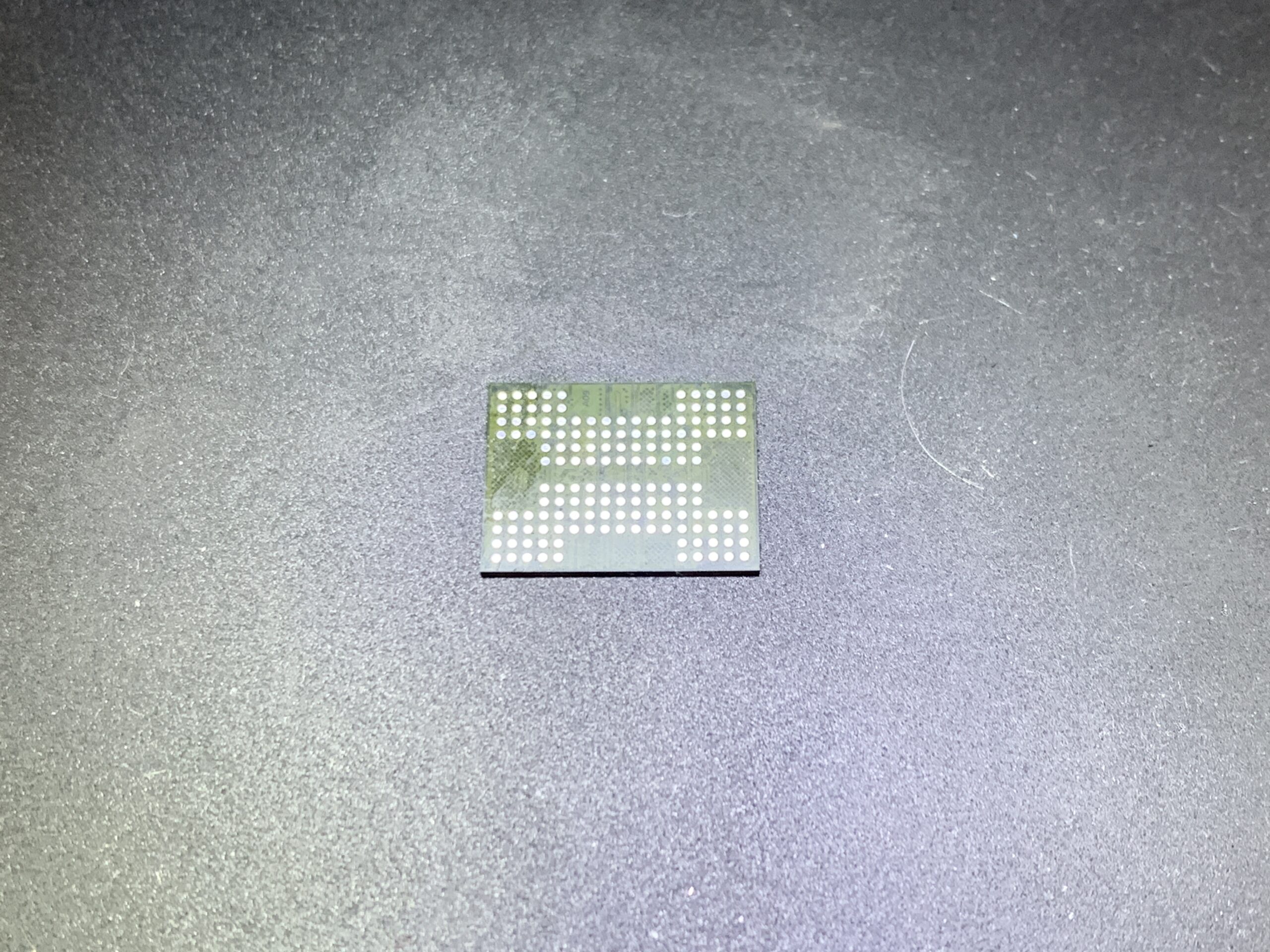

Finally, after removing all of the solder and debris from the BGA’s pads, clean the chip using isopropyl alcohol. Confirm the presence of all of the BGA pads. In the example below, the BGA chip features 152 connection pads.

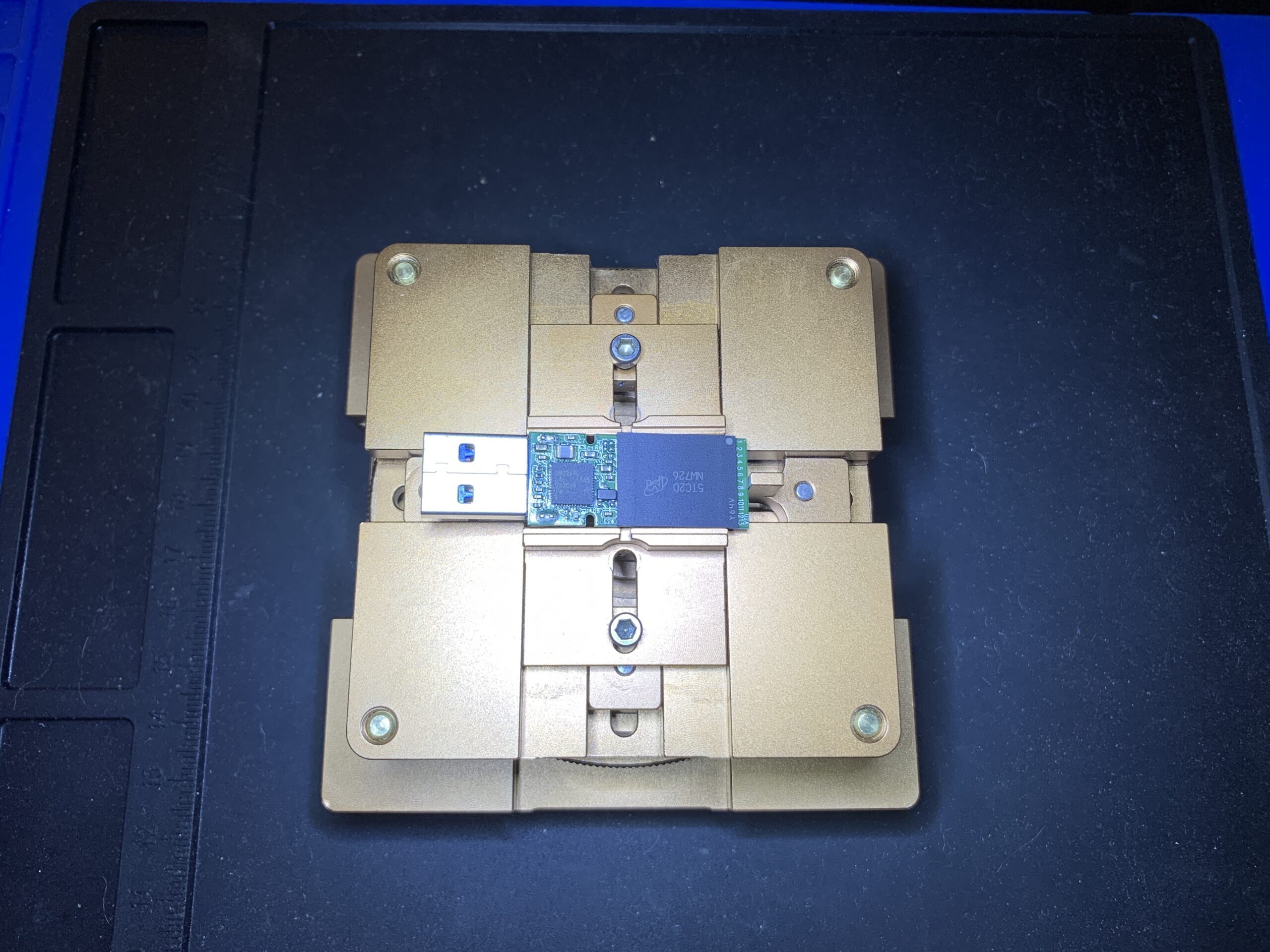

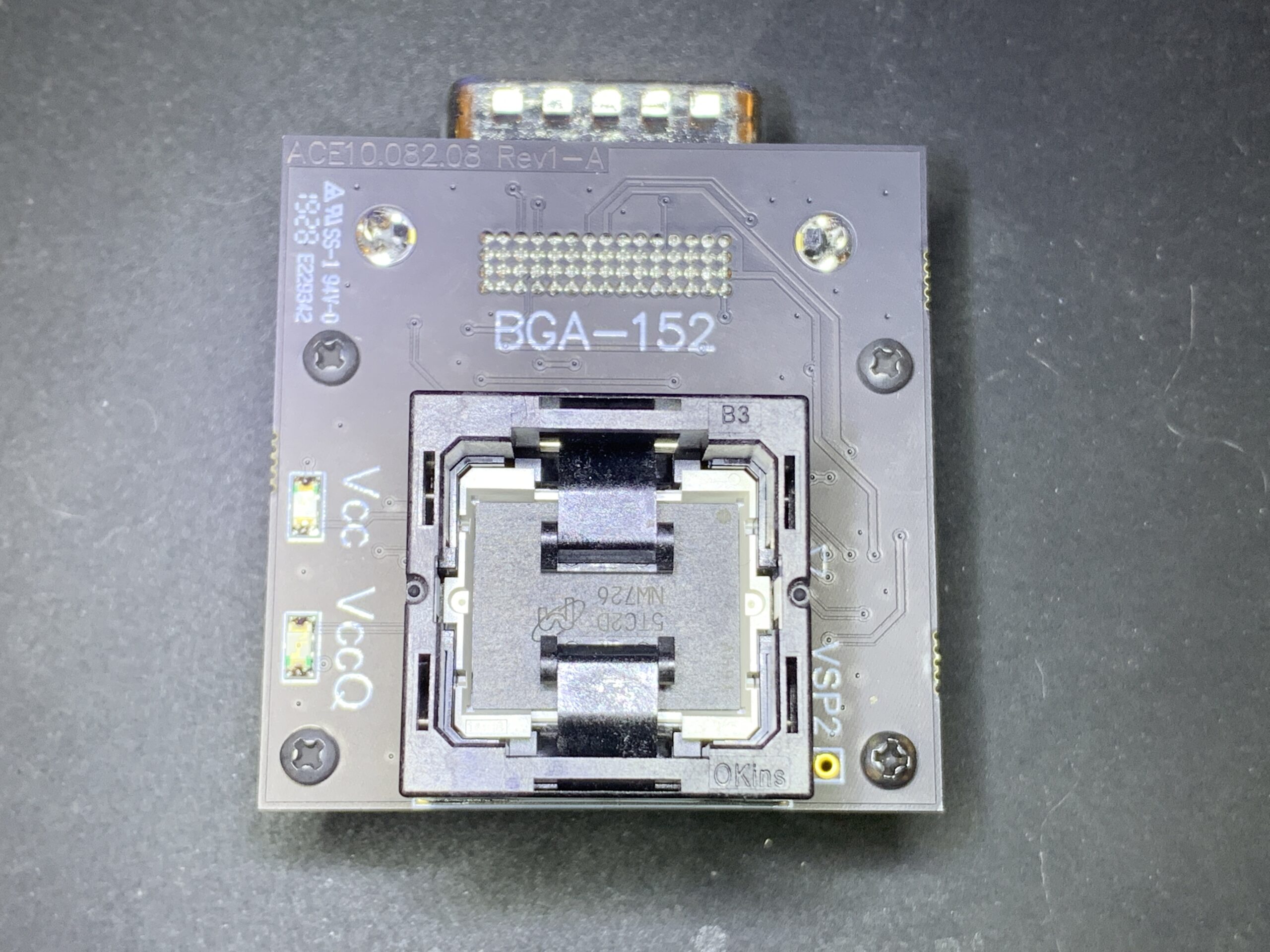

Mounting a BGA Chip In an Adapter

To mount the BGA Flash chip in the adapter, firstly flip the chip so the connection pads face downward. Next, orient the chip correctly for the adapter. In the example below, the corner of the BGA chip that contains the first connection is marked with a circle. Correspondingly, that corner of the adapter is marked with a triangle.

After orienting the BGA chip correctly, press downward on the adapter. This causes the two plastic arms to swing up and out of the way from the top. Next, place the BGA chip in the adapter. Finally, release the downward pressure from the adapter. This causes the arms on top to fold back down, holding the BGA chip in place in the adapter with very mild pressure.

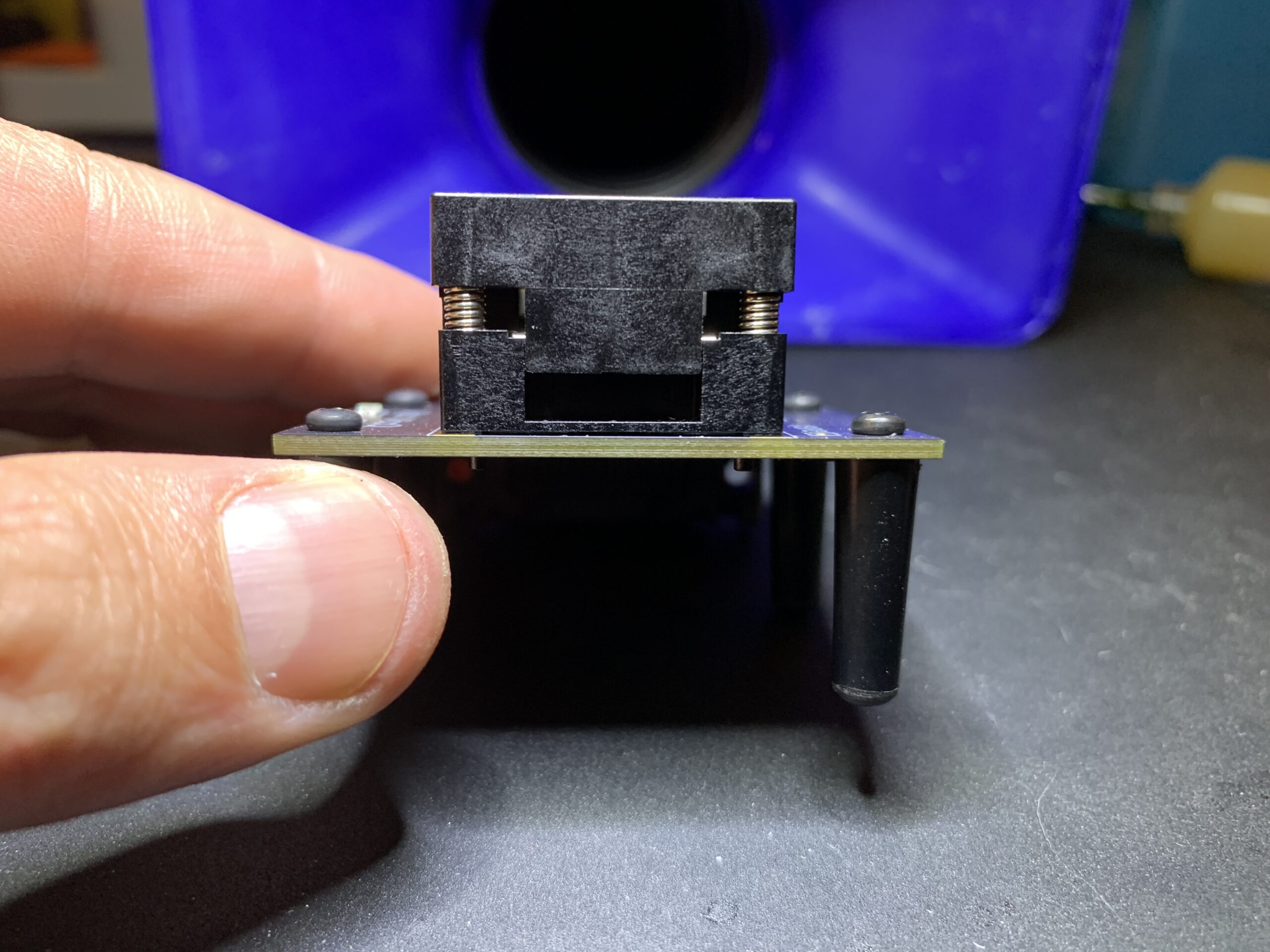

PC-3000 Flash BGA Chip Adapters

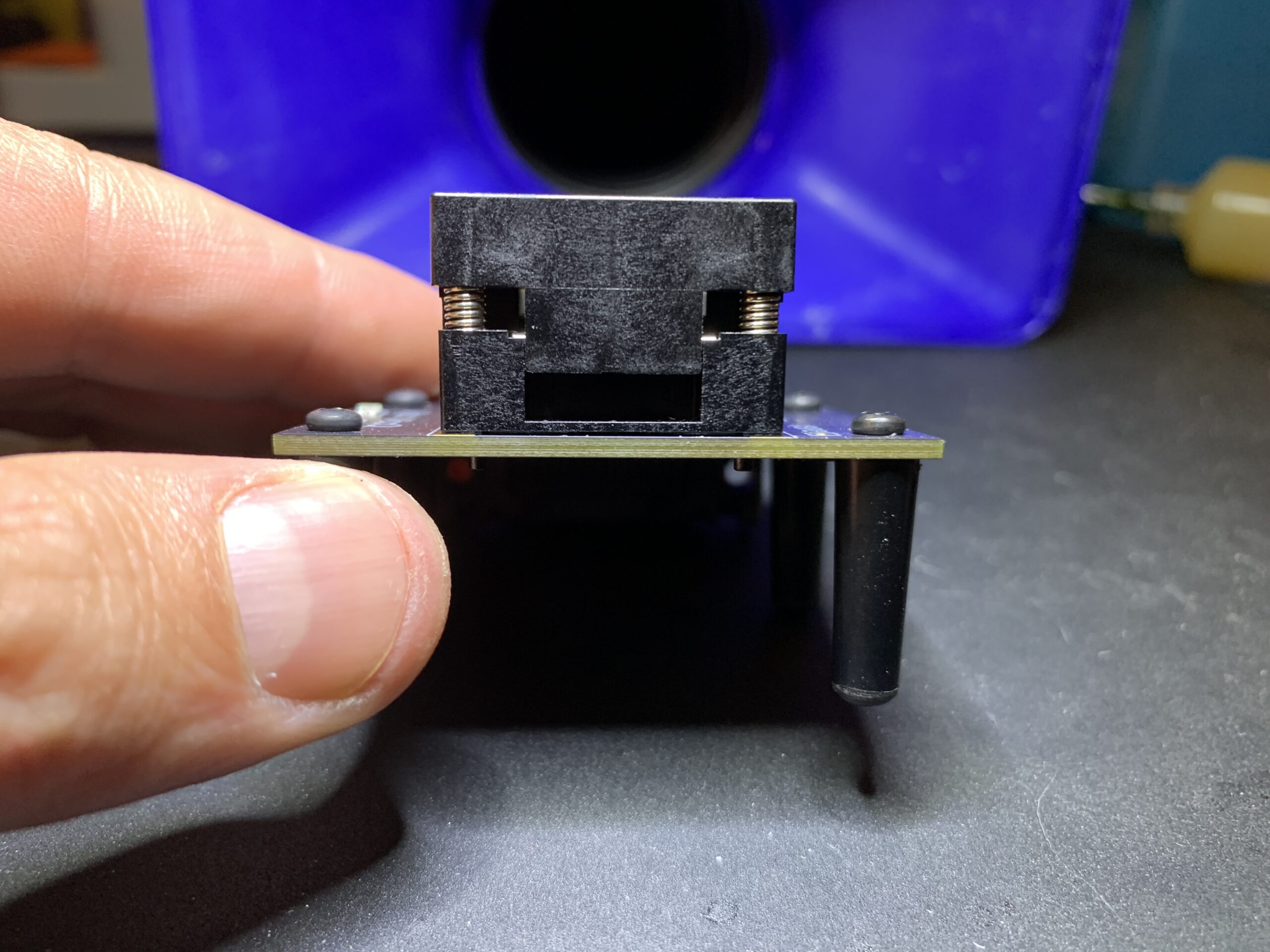

Seen from a side angle, the top plastic piece of the adapter is mounted to the bottom plastic piece using four springs. This configuration enables the adapters to clamp onto BGA microchips with the perfect amount of pressure.

Requiring neither soldering nor heat to mount, these PC-3000 Flash BGA Chip Adapters work perfectly for data recovery.

- Firstly, they reduce the amount of stress exerted on the BGA chips because do not require soldering of any kind.

- Secondly, the spring-mounted pogo pins never damage the BGA chip’s connection pads. Consequently, mounting chips in the adapters is always safe.

- Thirdly, mounting the BGA microchips in the adapters literally takes just one second to complete. Pogo pin adapters are some of the best adapters for data recovery.

IT-SD Related Articles